CALL NOW! 419-698-1601 | 1-800-548-3398

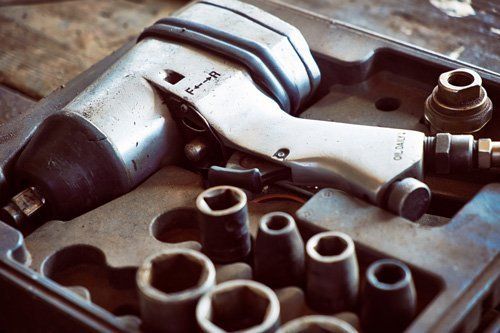

When choosing an air tool for your application, you may have the urge to go with the latest, greatest, and most powerful tool out there. However, before you purchase or rent an air tool, you need to make sure it's one you can use with your compressor. Here is what you need to know before you rent or buy a new air tool for your shop.

The Role of Cubic Feet per Minute Ratings

Before you make any choices, you need to know the capabilities of the air compressor you plan to use the new tool with. Your air compressor will have a CFM rating which indicates how much compressed air it can output by mass.

Your air tools will also have CFM ratings. The combined CFM of all the tools you use with the compressor cannot surpass the compressor's CFM.

What you must keep in mind is that you shouldn't max out the CFM of your compressor, nor should you choose a single tool that eats up all the compressor's CFM capacity. Even if you plan to only use one tool, you'll want to give your compressor some free space.

How you plan to use your air tool matters in this case as well.

Continuous Use or Intermittent Use

Will you need the tool always on and always available? Do your operations require you to use the tool constantly or will you only use it intermittently? These things will matter when choosing your air tool.

The air tool you have your eye on will have specifications for what kind of power it expects from your compressor. Pay attention to those specifications and adhere to them. Otherwise, you can end up with the air tool you want but not have the ability to use it properly.

Singular Tool or One of Many

If you're running multiple tools with your air compressor, you must make sure your air compressor can handle the combined CFM of those tools. To figure out if your air compressor can handle all the tools you need to run simultaneously, just add up the CFM of all the tools.

If you plan to switch between tools a lot, then use the tools with the highest combined CFM requirements as your max capacity number. After that, you should pad the number upwards to 25 percent just in case you need to add another tool in an emergency or for a special project.

The Role of Pounds per Square Inch Ratings

The PSI rating of your air compressor matters, but it's not as in depth as the CFM. The PSI rating of your air compressor lets you know how much pressure the compressor can output. The air tool you're considering will have a PSI rating denoting how much pressure it requires.

Most air tools require around 90psi to 100psi. Most modern air compressors output at least that much PSI. If you're not sure, just check your air compressor's PSI against the tool's needed PSI.

You may already use a tool with your compressor that has a higher PSI requirement than the tool you plan to rent or buy. In such a case, you're safe to pick up the tool if the CFM also works out for you.

Knowing the capacity and pressure requirements you can handle will help you choose the tool you need with confidence. These numbers may also help you figure out if you need to upgrade your current air compressor or add another to your operations.

When you're ready, or if you need help making the choice, contact West Equipment Company Co. Inc. to learn more about our selection of professional pneumatic tools.

CONTACT INFORMATION

Address:

1545 E. Broadway Toledo, OH 43605

Phone:

Fax

419-698-2540

Payment Options:

BUSINESS HOURS

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- -

- Sunday

- Closed

Contact us anytime in case of an emergency!

OUR LOCATION